Function:

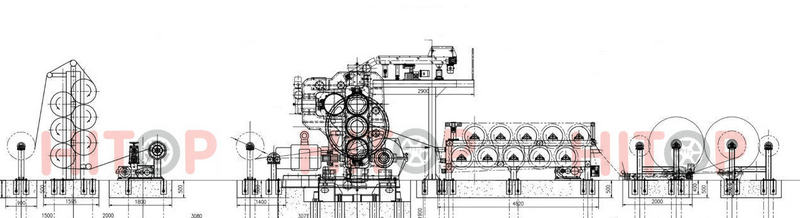

Rubberizing and frictioning of textile material, rubberizing of wire cord fabric, sheet and counter plate o rubber material, separation of fabric and film, as well as joint of multi-layer laminate film.

Features:

The roller is made of Chilled cast iron alloys, which has high hardness on surface,wear-resistance and durable life. Heating medium, such as steam, cooling water and heat-conducting oil can pass into the roller's cavity. So the working temperature can be adjusted in order to meet the technological requirements.

Roll spacing can be adjusted both by manual or electric mode. Roller bearing lubricating can adopt drier oil or dilute oil.

Size | XY-4I/L/Γ 630 | XY-4Γ 1200 | XY-4Γ1400 | XY -4Γ1500 | XY-4Γ 1730 | XY-4Γ 2130 | XY-4Γ 2430 |

Roller dia | mm | 230 | 360 | 400 | 450 | 610 | 710 | 810 |

Roller wording length | mm | 630 | 1120 | 1400 | 1500 | 1730 | 2130 | 2430 |

Roller ratio |

| 1:1:1:1 | 0.73:1:1:0.73 | 1:1.383:1.383:1 | 1:1.5:1.5:1 | 1:1.4:1.4:1 1:1.4:1.4:1.4 | 1:1:1 1:1.48:1 | 1:1.5:1.5:1 |

Middle roll linear speed | r/min | 2.1-21 | 2-20.1 | 3-26.3 | 2.5-25 | 8-50 | 8-50 | 2-20 |

Adjusting range | mm | 0-10 | 0-10 | 0-10 | 0-6 | 20 | 0-20 | 0.5-25 |

Min.calendering product thickness | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.15 | 0.15 | ±0.1 |

Calendering product width | mm | 100-500 | 500-920 | 1200 | 1250 | 1500 | 1900 | 2150 |

Motor power | KW | 15 | 55 | 75 | 110 | 160 | 185 | 280 |

Overall dimensions | L | mm | 3300 | 6600 | 6500 | 6580 | 7010 | 9800 |

W | mm | 940 | 1620 | 1970 | 2460 | 4150 | 4260 |

H | mm | 2350 | 2490 | 2740 | 2920 | 3730 | 5720 |

About weight | T | 4.8 | 14.6 | 18.6 | 33.5 | 62 | 100 | 126 |

Model | XY-3I 630 | XY-3I 1120A

XY-3l1120A | XY-3I 1400 | XY-3I 1200

XY-3I 1500 | XY-3I 1730 | XY-3I 2130 |

Roll diameter (mm) | 230 | 360 | 400 | 450 | 610 | 710 |

Working-length (mm) | 630 | 1120 | 1400 | 1200(1500) | 1730 | 2130 |

Roll speed ratio | 1:1:1

1:1.42:1 | 1:1:1 0.733:1:0.733 | 1:1:1

1:1.383:1 | 1:1:1

1:1.5:1 | 1:1:1

1:1.4:1 | 1:1:1

1:1.48:1 |

Middle-roll linear speed (m/min) | 7.97 | 7.0-21.06 | 8.8-26.39 | 8.36-25.08 | 5.4-54 | 8-50 |

Adjusting nip range (mm) | 0-7 | 0-10 | 0-10 | 0-6 | 0-20 | 0-20 |

Min. product thickness (mm) | 0.2 | 0.2 | 0.2 | 0.15 | 0.15 | 0.15 |

Product width (mm) | 100-500 | 500-920 | 1200 | 1100(1400) | 1500 | 1900 |

Motor power (kw) | 7.5 | 40/13.3 | 55/18.3 | 75/25 | 132 | 185 |

Overall dimensions (mm) | 2570×740x1500 | 5550×1640x2120 | 6500×1500x2400 | 7120(7420)x2200x2900 | 7010×3950×3730 | 7650×4560x 4080 |

Weight (kg) | ~4200 | ~12750 | ~26000 | ~27000 | ~52000 | ~67000 |